|

|

|

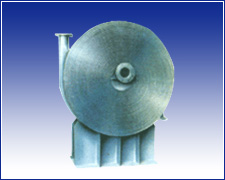

I type

|

II type

|

|

|

|

I type

|

III type

|

|

|

|

Structure and performance Structure and performance1, this equipment is made by rolling two pieces, forming two even spiral channels, two kinds of heat transfer medium can completely counter-current flow, greatly enhance the heat transfer effect,even the two medium with small temperature difference, can also achieve theideal heat transfer effect.

2, Adapter tubes on the shell adopttangential structure, with small local resistance, due to the curvature of the spiral channels is uniform, liquid flow inside the device does not turn severely, the general resistance is small, thus can improve the design flow rate to a higher heat transfer ability.

3, The end face of spiral channel of typeI undetachable type spiral plate heat exchanger adopts welding sealing, thus has high tightness.

4, The structure principles of type II detachable spiral plate type heat exchanger is basically the same as the detachable heat exchanger, but one channel can be detached for cleaning,especially for heat exchange of sticky liquid, liquid with precipitation.

5, The structure principles of type III detachable spiral plate type heat exchanger is basically the same as undetachable heat exchanger, but the two channels can be detached for cleaning, it can apply for a wide range.

6, Nominal pressure of spiral heat exchangers can be classified into PN0.6, 1.0, 1.6, 2.5 MPa (refer to the biggest work pressure that single channel can withstand). According to the material, they can be classified into carbon steel and stainless steel. Users can choose according to the actual process.

7, When single equipment can not meet the application requirements, can use combination of muti sets, but the combination must comply with the following provisions:

Parallel combination, serial combination, same distance of equipment and channel. Mixed combinations: a channel in parallel, achannel in series.

Part of the heat exchanger specifications are listed as follows: Part of the heat exchanger specifications are listed as follows:

Stainless steel PN0.6 1.6 MPa, acid-proof undetachable type (type I) spiral plate heat exchanger

Nominal heat transfer area m2

|

|

Calculated

Heat transfer

area m2

|

Productivity m3 / h when flow speed

1 m/ces

|

Nominal diameter of adapter tube

|

|

|

|

|

|

|

|

6

|

1.0

|

3.89

|

40

|

I 6,I 16B1-0.2/300-6

|

44

|

50

|

|

|

6

|

2.1

|

3.89

|

40

|

I 6,I 16B2-0.2/400-6

|

78

|

85

|

|

|

6

|

4.4

|

8.2

|

50

|

I 6,I 16B4-0.4/400-6

|

131

|

135

|

10

|

4.5

|

17.3

|

80

|

I 6,I 16B4-0.5/450-10

|

129

|

133

|

10

|

4.8

|

13.7

|

70

|

I 6,I 16B4-0.4/500-10

|

161

|

205

|

|

|

6

|

7.3

|

8.21

|

50

|

I 6,I 16B8-0.4/500-6

|

212

|

215

|

10

|

7.85

|

17.3

|

80

|

I 6,I 16B8-0.5/550-10

|

235

|

273

|

10

|

7.3

|

20.90

|

80

|

I 6,I 16B8-0.6/500-10

|

237

|

275

|

|

|

6

|

11.1

|

8.21

|

50

|

I 6,I 16B10-0.4/600-6

|

295

|

355

|

10

|

11.5

|

17.3

|

80

|

I 6,I 16B10-0.5/650-10

|

315

|

405

|

10

|

11.2

|

20.90

|

80

|

I 6,I 16B10-0.6/600-10

|

305

|

395

|

|

|

6

|

16.9

|

12.54

|

70

|

I 6,I 16B15-0.6/600-6

|

415

|

490

|

10

|

14.72

|

17.3

|

80

|

I 6,I 16B15-0.5/760-10

|

405

|

575

|

10

|

15.0

|

28.1

|

80

|

I 6,I 16B15-0.8/600-10

|

400

|

570

|

14

|

15.6

|

39.3

|

100

|

I 6,I 16B15-0.8/700-14

|

505

|

680

|

|

|

6

|

21.7

|

8.21

|

50

|

I 6,I 16B20-0.4/800-6

|

540

|

710

|

10

|

21.0

|

20.90

|

80

|

I 6,I 16B20-0.6/800-10

|

555

|

735

|

14

|

20.9

|

39.30

|

100

|

I 6,I 16B20-0.8/800-14

|

660

|

830

|

|

|

10

|

26.6

|

29.90

|

80

|

I 6,I 16B25-0.6/900-10

|

610

|

950

|

14

|

26.9

|

39.20

|

100

|

I 6,I 16B25-0.8/900-14

|

720

|

1060

|

|

|

10

|

28.2

|

28.10

|

100

|

I 6,I 16B30-0.8/800-14

|

750

|

1180

|

14

|

32.2

|

39.20

|

100

|

I 6,I 16B30-0.8/1000-14

|

980

|

1370

|

|

|

10

|

45.4

|

35.30

|

100

|

I 6,I 16B40-1.0/900-10

|

1130

|

1515

|

14

|

40.2

|

19.4

|

125

|

I 6,I 16B40-1.0/1000-14

|

1200

|

1630

|

|

|

10

|

53.9

|

35.3

|

100

|

I 6,I 16B50-1.0/1000-14

|

1360

|

1755

|

|

|

10

|

61.05

|

35.3

|

100

|

I 6,I 16B60-1.0/1100-10

|

1920

|

2112

|

14

|

60.08

|

49.40

|

125

|

I 6,I 16B60-1.0/1200-14

|

2000

|

2200

|

|

|

10

|

81.83

|

35.3

|

100

|

I 6,I 16B80-1.0/1200-10

|

2560

|

2816

|

14

|

80.9

|

49.40

|

125

|

I 6,I 16B80-1.0/1400-14

|

2667

|

1934

|

|

|

10

|

101.9

|

35.3

|

100

|

I 6,I 16B100-1.0/1300-10

|

3200

|

3520

|

14

|

100.06

|

49.40

|

125

|

I 6,I 16B100-1.0/1500-14

|

3333

|

3666

|

|

|

10

|

115.5

|

35.3

|

100

|

I 6,I 16B120-1.0/1500-10

|

3870

|

4257

|

14

|

119.0

|

49.40

|

125

|

I 6,I 16B120-1.0/1700-14

|

4020

|

4422

|

|

|

14

|

128.80

|

49.4

|

125

|

I 6,I 16B130-1.0/1750-14

|

4241

|

4665

|

18

|

129.09

|

63.5

|

150

|

I 6,I 16B130-1.0/1967-18

|

4462

|

4908

|

|

|

14

|

148.1

|

49.4

|

125

|

I 6,I 16B150-1.0/1890-14

|

4702

|

5172

|

18

|

148.2

|

63.5

|

150

|

I 6,I 16B150-1.0/2010-18

|

4962

|

5458

|

|